Environmental Biodegradable Additive

Development of Degradable Plastic

There have been three development generations of bio-degradable plastic.

The first was starch based plastic, PLA & PSM consist of corn starch.

The 2nd generation was oxo-biodegradable ( oxo, d2W ) conventional plastic.

The 3rd generation is micro-biodegradable conventional plastic

PLA ( polylactic acid )

PLA, PSM are corn based bio-degradable plastic, was said to be the first generation of bio-degradable plastic and primary discovered /made in 1950 ( mid of last century ).

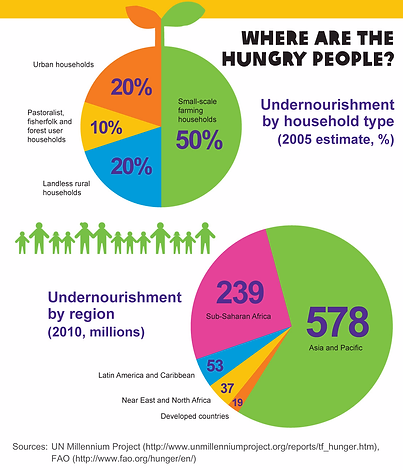

As PLA is preliminary made from corn, which is a major food source. However, if all of the disposable plastic in the world are switching to PLA plastic, which means that around 238 millions tons of corn would be used to make plastic in each year. Prices of corn would rise dramatically, which affects our food supplies ( corn is the feeding stocks for cattle, pig & chicken ) and put up the inflation. ( corn flakes, the cereals in our breakfast ). And third world hunger would increase even more dramatically.

Remarks : 0.9 billion hunger people in the third world, according to UN Report in Year 2010. There are currently 0.821 billion hunger people in the third world, according to UN Report in 2018.

Furthermore, PLA isn’t a very good plastic.

-

It imparts an off taste to water, when used for water bottles.

-

It melts, when used as soup spoons.

-

It is weak, which meaning the thicker and heavier, more plastic to be used.

-

It has a short shelf life, sometimes becoming a sticky mess while still in the warehouses.

-

NO recyclers ( USA ) accept it PLA for recycling, except the company that manufacturing it.

PLA plastic can only be recycled with all other PLA plastic, and produced into new PLA plastic.

Once PLA plastic mix with other conventional plastic, this ruins the whole recycled plastic batch.

Naturworks, states that it will not bio-degradable in any natural environment, nor in landfills. PLA ( polylactic acid ) is only bio-degrades in commercial compost facilities, and many commercial compost facilities in USA ( factory ) are refused to accept PLA, because PLA makes the compost too acidic.

90% of recyclers would not accept PLA bottles, in one of survey in USA. Only few commercial compost factories accept PLA, but a few amount with a limited appetite of PLA, because it adversely affects the compost batch.

PLA requires elevated heat in compost processes generates to compost. The most peculiar thing about PLA compostable, is that it leaves no residue in compost, hence it gives no contribution to the humus.

*Reference :

Oxo-Degradable

The 2nd generation plastic is oxo-degradable plastic. The additives are typically organic compounds of transition metal, such as iron, nickel, cobalt and manganese. Applications using oxo-degradable plastic bags, refuse sacks, flexible packaging and agricultural mulch films. Oxo-degradable have better advantages than PLA:

-

Invulnerable to water

-

It could be cycled, in mixing with the other plastic batches.

( This could not apply in HK, as a lot of cycled plastic are widely apply on the external playground as introduced by HK Leisure & Cultural Services Department. Sunlight /UV will reduce the product life, and fragments into small pieces ).

-

Didn’t diminish the grain supply ( not made from corn )

-

Stronger.

-

Less expensive.

Oxo-degradable plastic was well established and widely used in Europe, Middle East, Mid-America, the large grocery supermarket uses oxo-degradable plastic bags in their food packaging, package, t-shirt bags etc. And oxo-degradable plastic is becoming common in China and India, after widely advertising in markets.

Oxo-degradable plastic require certain environmental factors for allowing degrading process commence:

-

oxygen ( aerobic )

-

heat

-

sunlight / UV

-

mechanical stress ( external force to break the plastic in fragments )

All these circumstances do no exists, when the oxo-degradable plastic deeply buried in landfill !

That oxo-degradable do degrade when exposed to either sunlight or heat ( around 60 oC ) is not in doubt. The additives serve to catalyse and accelerate break-down of the polyethylene ( PE ) by a process known as oxidative degradation. This degradation process causes deterioration in the strength of the plastic, which becomes brittle and easily fragments into small pieces. The length of time to degradation of oxo-degradable plastic cannot be predicted accurately, because it depends so much on the environmental conditions and the amount of additives in the plastic. This means that the degradable process is much faster in Africa and India, than other areas in northern hemisphere ( most population are located in northern of our planet ).

Oxo-degradable plastics are not compostable, according to established International Standards EN13432 and ASTM 6400. Oxo-degradable plastics should not be included in waste going for composting, because the plastic fragments and heavy metal oxides remaining after the composting process, it might affect the quality and saleability of the compost, and pollute the water & soil.

Finally, TESCO (largest supermarket in UK) had stopped using oxo-degradable plastics shopping bags, citing a research study by DEFRA & Loughborough University ( Department for Environment Food and Rural Affairs ) in January 2010.

Nowadays, more & more European Countries ( France, Spain, Netherlands ) are banning the use of oxo-degradation plastic, after EU Commission had decided a new plastic strategy to restrict the use of oxo-degradation plastic since 16 January 2018. Many Worldwide & International well-known Companies and NGOs had endorsed that “ Oxo-degradable plastic packaging is not a solution to soil or marine pollution and does not fit in a circular economy. It contributes to microplastic pollution and poses an environmental risk”.

*Reference :

EC Committee RESTICT OF USING OXO-DEGRADABLE

Micro Bio-Degradable Plastic

Lets us introducing more about EBA now.

EBA is an authentic and evidence based environmental approach to product development that is providing leadership for Clients and taking core in environmental concerns.

EBA meets ASTM testing standards for biodegradation and composing of plastic products.

-

EBA plastic contains a safe, non-toxic, organic based additive.

-

EBPA plastic packaging contains an FDA ( US Food & Drug Administration ) approved organic based additive, and can use on food packaging.

-

EBA additive is beneficial to the environment, while maintains their strength & integrity of plastic products, no changes the shelf life of regular plastic until the presence of micro-organisms.

-

EBA additive changes the molecular structure, once the material is discarded in landfill. Therefore EBA is a degradable plastic in which the degradation results from the action of naturally occurring microorganisms, such as bacteria, fungi and algae.

-

EBA bio-degradable plastic that undergoes biological degradation during composing to yield carbon dioxide, water, methane ( CH4, energy ), organic compounds and biomass at a consistent rate with other compostable materials and leaves no visually distinguishable or toxic residues.

( In Hong Kong and USA, all our present landfill have the pipes laid for collecting methane, which can be used as town gas or generated electricity )

-

EBA bio-degradable processes can occur in both aerobic and anaerobic conditions, which is common landfill conditions. And no extra industrial composting is required.

-

EBA plastic can meet current recycling standards, with no extra processes required. All these can be used in normal recycling facilities.

Almost every industry in the World uses plastic. EBA additive can be tailored and applied to most plastic. EBA additives can be blended with these plastic for a bio-enhanced products.

-

HDPE, LDPE, LLDPE

-

PP

-

PET, PETG

Other EBA additive can works with:

-

EVA

-

UVL

It can mix with any plastic color dyes, and printed with any ink color.

Therefore, EBA is a new environmentally sensitive approach into every aspect of our Hospitality Industry. Disposable plastic packaging is always considered and constantly reviewed to ensure it is eco-responsible as possible, which includes personal cosmetic containers ( such as Cosmetic PE Tubes, Cosmetic PET Bottles ), personal cleaning accessories ( such as toothbrushes, razors, combs etc…. ), and external protective disposable polybags.

EBA plastic using our exclusive formula will be equal to standard plastic packaging in strength, appearance and integrity. This allows us to provide high quality finish products, and gives you advantage of degradability as well as competitive pricing which helps you to maintain a low budget on costs control. EBA is your practical solution to packaging with a conscience.

We ( EBA ) takes this seriously about making a difference to the huge global environmental problem. So we have developing an unique and exclusive range of hotel amenities accessories, of using EBA additive and allows the quick decompose in landfill.

We trust that everyone of you are highly value corporate social responsible company. In the hospitality industry, we should be strongly conscious of the environmental from the concerns of society, clients, hotels and hotel guests. Too much plastic waste ends up in landfill and global waste consumption is an enormous issue. Normal plastics is not bio-degradable, therefore they will stay in landfill forever. However, EBA plastic will bio-degrade under normal landfill conditions. It will not cause an issue for the landfill waste in the long term.